Reorder Point Definition & Formula + Calculator

Reorder quantity, on the other hand, is the quantity of stock to be ordered when the stock reaches the reorder point. Generally, the service level of an organization’s product lies between 90% to 100%. The soft drinks are delivered in 2 days, but the snacks are delivered in 3 days. But when the company does maximum production, it requires 14 packets per day. Safety stock is the number of materials or products stocked in the warehouse during unexpected emergencies.

Reorder Point Calculation

This is calculated by determining the safety stock level and the stock required to service needs during the reorder lead time. ShipBob is an order fulfillment solution that features built-in inventory management software, giving you precise control over your inventory. You can check inventory counts at each fulfillment center and set automatic reorder levels, so you are notified when stock is running low. Regular monitoring and adjustment of these inputs are essential to maintain an effective reorder point strategy over time. If you sell more than one product category in your eCommerce store, you’ll likely have more than one supplier.

- This allows you to easily determine when you are nearing your reorder point and take appropriate action.

- Almost everything we need can be found on the internet and is only a few clicks or taps away.

- For items or sub-assemblies that are manufactured in-house, lead time is referred to as factory or production lead time.

- You’ll have enough shirts left on hand units – to sustain you until the next delivery of shirts.

- All we need to do now is add your lead time demand number to your safety stock number.

What is the difference between safety stock and reorder point?

This article gives you the reorder point formula and how to calculate your reorder point. Over those three months (or 92 days) that averages out to 1.5 units sold on average per day. While implementing a reorder point strategy may not address the whole puzzle, it provides a more exact basis for your stock replenishment schedule. The more things you can take the guesswork out of, the better for your organization’s bottom line.

- But in reality, some of your suppliers may not be able to deliver the materials on time because of their problems.

- The reorder point formula lets you optimize your inventory ordering so you can meet demand without ever running out.

- Let’s say the speakers have a lead time of 4 days and the monitors have a lead time of 12 days.

- Having the required stock in your inventory is essential to keep customers satisfied and minimize losses.

- Your delivery team can take digital proof of deliveries to minimize the delivery time and increase efficiency.

What are the advantages of ROP advertising?

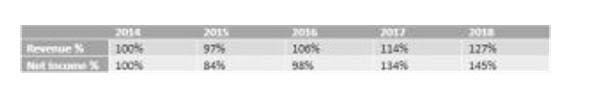

ROCE may need adjustments, including subtracting cash from capital employed to get a more accurate measure of ROCE. The long-term ROCE is important, where investors favor companies with stable and rising ROCE numbers. Return on capital employed (ROCE) and return on assets (ROA) are two similar profitability ratios investors and analysts use to evaluate companies. The ROCE ratio is a metric that evaluates how efficiently a company’s available capital is utilized.

How to Calculate Reorder Points with the ROP Formula

Roper Technologies announces first quarter financial results – GlobeNewswire

Roper Technologies announces first quarter financial results.

Posted: Fri, 26 Apr 2024 07:00:00 GMT [source]

As the owner or inventory manager, your priority should know when to order new stock. As a manufacturer, some of the questions constantly going through your head are most probably about when you should order your raw materials next, and how much to order. You omnichannel fulfillment partner that’s an extension of your brand, from unboxings to 2-day shipping.

Reducing excess inventory

You can use a free reorder point calculator or manually use the reorder formula to replenish inventory and meet customer demand with finesse. So once your stock hits 110 t-shirts, you will need to place a new order with your supplier. The average amount of a product you sell on a given data helps in accurate reorder rop meaning business point calculation. Analyzing your reorder point in your inventory management process can help you align with the sales trends and maintain the inventory needed for desired customer experience. You may purchase items in your inventory from various vendors, and different vendors have different lead times.

Track and manage time

Different vendors have different lead times, so you’ll need to calculate reorder points for each product category separately. For example, those following lean inventory practices or a just-in-time management strategy. If you only carry enough stock to meet current demand, you’ll need to adjust your ROP formula to reflect the absence of safety stock.

- Knowing your ROP helps you place an order with enough time to receive, process, and restock it.

- With the rising customer demands, these ineffective methods can result in business losses and minimize your chances of business success.

- To calculate a reorder point with safety stock, multiply the daily average usage by the lead time and add the amount of safety stock you keep.

- It helps mitigate risks and ensures that the desired service level is maintained, even in unforeseen circumstances.

- To accurately calculate your lead time demand, it is crucial to utilize historical data for forecasting demand.

- Calculating the point of re-ordering lets you optimize your inventory.

- Safety stock is the inventory a company holds in its warehouse to avoid a shortage of materials during sudden increasing demands.

For Supplier B, your reorder point will be higher because you need to account for more stock days between your order and when new stock arrives. You source the https://www.bookstime.com/articles/tax-shield shirt from Supplier B, who has a typical lead time of 7 days. When establishing a reorder point, you want to avoid repeatedly pulling from your safety stock.

- Circulation, color, frequency, section, and day of the week are also important factors.

- Knowing which products are hot items and those that are cooling off allows you to jump on new opportunities and adjust your stock to meet increased demand.

- Within a few clicks, you can create optimized and shorted delivery routes.

- Many aspects of your business rely on third parties to keep operations running smoothly.

- It also helps avoid the profit loss from placing orders too early, which can cause the stock to pile up.

Leave a Reply

Want to join the discussion?Feel free to contribute!